Our vacuum pads, vacuum cups, suction cups, suction pads and rubber tips are used widely and suitable for many types of pick and place equipment and machines in any kinds of manufacturing and industries e.g. automation system, vacuum system, pneumatic gripper, vacuum gripper, gripper system, end of arm tooling (EOAT), robot tooling, robotic arm, vacuum ejector, vacuum inlet, vacuum fitting and so on.

4 components of vacuum pads you need to know about before you choose the right vacuum pad for your work.

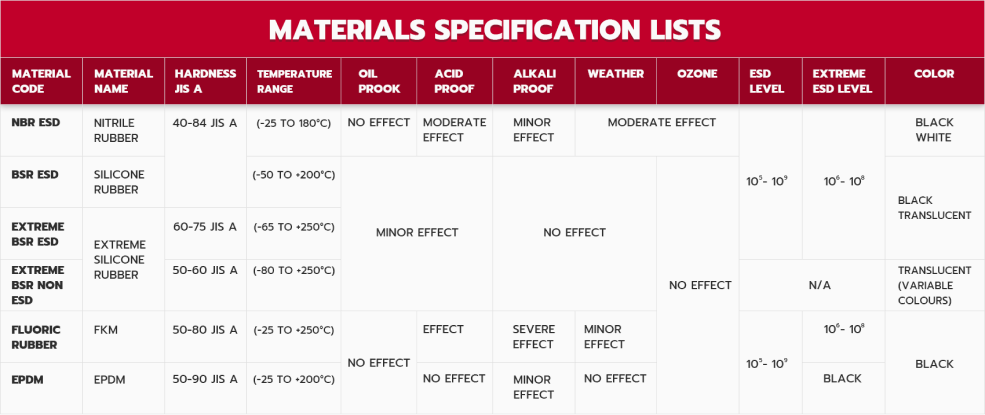

| Vacuum pads types | Vacuum pads materials | Hardness JIS A | Surface resistance – ESD |

|---|---|---|---|

| – Flat vacuum pads – Single bellow – Double bellows – Multiple bellows | – Nitrite rubber (NBR) – Silicone rubber (BSR) – Fluoric Rube (FKM) – EPDM | – Standard hardness is 60 JIS A – Hardness can be adjusted between 40 (softest) to 90 JIS A (hardest) | – non ESD vacuum pad -for general purpose work piece. – ESD safe vacuum pad -for ic chip and electronic components – ESD Class 1: 105-109 – ESD Class 0: 106-108 |

3 steps to choose the right vacuum pads for your work.

Step 1: From the below table, you will know what type of vacuum pads you are looking for.

4 different types of vacuum pad for different types of pick and place application.

| Vacuum pads Types | Flat vacuum pads | Single bellow | Double bellows | Multiple bellows |

|---|---|---|---|---|

| Image |  |  |  |  |

| Applications | For workpieces with flat surfaces | For workpieces with uneven and arched surfaces | For workpieces with uneven and arched surfaces. More folds give more flexibility. | For workpieces with uneven and arched surfaces. More folds give more flexibility. |

| Lifting force | The best | Moderate | Moderate | Less |

Step 2: Choose the right material for your vacuum pads by referring to the below Materials Specification Lists